1930 Model A Ford Sedan (1957 to 1960)

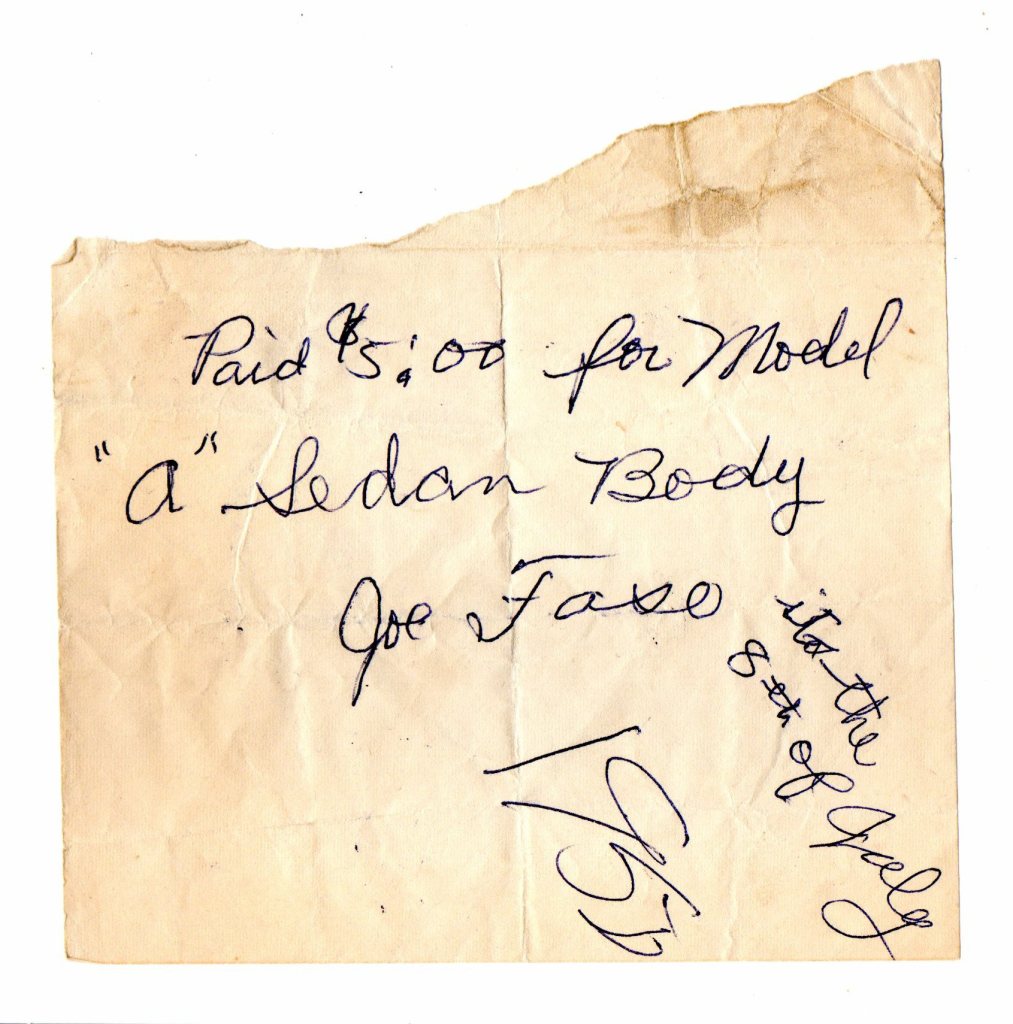

Like my first car, the body style of my second car wasn’t my first choice, it happened by accident. My plan was to use a later Ford roadster pick-up body on the frame and running gear that I kept from my first car. The later 1926 and 27 Ford bodies were slightly larger in the driver’s compartment than a 1923 body, making it a lot more comfortable for two people. After 4 or 5 months of looking for a later roadster pick-up body, I happened to stop by a friend’s house, Joe Faso who lived with his grandparents on their Alice Ave. farm. While there I noticed a 1930 Model A sedan body sitting on a couple of saw horses that Joe had picked up during his travels, and was now interested in selling. After looking the body over, I found it to be in very good condition, and decided to buy it. Joe cut me a super deal, selling it for $5.00. Although I really wanted a 1927 Ford roadster pickup, the Model A sedan was a good second choice.

To get the sedan body home, I rolled my frame/chassis (with help from a friend) from my parent’s house to Joe’s grandparent’s farm where we slid the body onto the chassis and rolled it back to my parent’s house. Rolling the chassis around town to pick-up parts may seem like a lot of work today, but we never thought of it as work, it’s just the way we did things back then.

My plan was to make the sedan into a hot rod. At the time, most “hot rods” were being built using mostly stock parts that were modified using ideas from drag race, or circle track cars. I started out to do a few of the popular modifications to the sedan, but ended up doing just about every trendy thing I had seen in the car magazines. And now that I had a sedan body instead of a roadster, I would have another trendy thing to do, chop the top (to reduce the sedans overall height).

One of the trends was the car’s ‘rake’. Rake in this case was the angle the car set in relation to the ground (front lower than the rear). This was very popular at the time, and a must for a hot rod. There were a couple ways to accomplish this; one was to use small tires on the front, and large tires on the rear. Another was to use a dropped front axle, and I decided to do both. I picked up some large rear tires (8.20 x 15”) from the used tire pile at our local neighborhood Shell service station, and I had Mor-Drop Axles in Oakland, Calif. make me a dropped front axle. Together they created a slight rake, but it wasn’t enough. I wanted the rake to be a little more radical. So, I used a third method to lower the front end of the car, a suicide front crossmember, which drops the frame down behind the front axle. The crossmember was a part that had to be custom made using steel plate, tubing, and a lot of welding, something I didn’t have any experience with. I was in my second year of high school metal shop, but so far I had only worked with light gauge sheet metal and copper.

I knew roughly what I wanted the crossmember and its mounting bracket to look like, so I mocked up the axle, frame, and spring, and made templates out of cardboard of the parts I needed to make. At the time my father was the manager of Formway Machine shop in Los Altos, Ca. and he usually went to the shop on Saturdays to get caught up on his paper work. One Saturday I tagged along, and with his help and advice, I spent the day making the crossmember parts. This was my very first project designing and creating steel parts, and my introduction to heavy machinery, and I really enjoyed it. This would also be the first of many Saturdays I would spend at the machine shop making other parts for my car.

Some of the other modifications that required the machine shop to create were splitting the front wish bones and their frame brackets, along with custom front and rear shock absorber mounts. The popular shock absorber at the time was a Monroe 50/50 shock and, not having the money to buy a new pair of shocks and needing a pair for mock-up purposes, I rummaged through a couple of local gas station junk piles to find a pair of shocks with double grommet ends that would work on my chassis.

Other changes to the sedan that didn’t require creating a part were replacing the Model A rear axle housing with a 1940 Ford rear housing, and replacing the early mechanical brakes with hydraulic brakes from a 1939 Ford. Most of these jobs just required unbolting a part and bolting in the replacement part. To find these heavy mechanical parts, I would go through the junk piles at our local car repair shops, or sometimes go to an auto wrecker’s. One shop we often went to was Jack’s Garage, located on the old Mountain View/Alviso road close to Alice Ave. Jack had a fairly large junk pile of used car parts behind his shop and didn’t mind us picking through it. When we found something we wanted, he usually only charged us a couple of bucks no matter what it was. We were a little afraid of Jack. He was Japanese and always wore a greenish looking Japanese naval cap. He spoke in broken English, didn’t talk much, and always seemed to be a little angry. We learned overtime that was just him and his way of talking. We often wondered what he did during the Second World War; was he sent to an internment camp, or did he work for the Japanese during the war? We never found out, but either way we liked him, and he always seemed happy to see us.

During my high school freshman summer vacation, I decided to chop the top on the sedan. Another thing I knew nothing about except for what I had read in the car magazines, and I was a little worried about aligning the two body parts after they were cut apart. As it turned out, other than the welding, it wasn’t that hard of a job. I marked the body with masking tape where I was going to make the cuts, and with only a hack saw, and a single handheld hack saw blade wrapped in a rag, I cut the top off. It was slow work, taking a couple of days.

Using every type of c-clamp we had at home, and some my father brought home from work, I clamped the top to the body posts. The fit was very close to a perfect match. Not having gas welding equipment at home, my father borrowed an oxy acetylene torch set-up from his work. I only had a little experience with gas welding in high school, so my father gave me a crash course on welding sheet metal, and after a couple days of practicing, I felt comfortable enough to start welding the top back on. Following what I had read on “chopping a top”, I carefully tack welded the sheet metal body parts back together, welding every half inch or so, moving from side to side, being careful not to warp the metal. After I completed welding the body, I cut down the doors and windshield, fitting them to the body as I tack welded them back together. All together it took about three weeks to complete. I thought the job turned out pretty good, and although I never had the cut/weld line finished by a real body man, I was told by one that it wouldn’t take much work to finish off the body work.

My original plan was to use a 1949 Ford or later flat-head engine in the sedan. But when I found out Mike Bailey was selling the Oldsmobile engine out of his 1939 Ford Sedan, I changed my mind and decided to buy his engine. I don’t remember what I paid for it, or how I moved the heavy Oldsmobile engine to my parent’s house, but somehow I got it there. I did do a valve job on the heads so I may have taken the engine apart to move it. Once home, I cleaned and painted it, adding a pair of Edelbrock finned aluminum valve covers to dress up its appearance.

Hot Rod magazine had been promoting sanctioned drag racing as an alternative to street racing during the 1950s, and by the late 1950s it had become a fairly big sport. I attended my first drag race in 1957 which made a very big impression on me. There were two local drag strips in the area, one in San Jose (named Little Bonneville), and the other in Half Moon Bay. Both tracks used existing airport runways as the race track and were only opened once or twice a month. That changed in June of 1959 when Fremont Drag Strip opened. It was different from the other drag strips in the area, as it was built and designed specifically as a drag strip with a permanent track, elapsed time and speed clocks, and it was opened every Sunday.

Not long after Fremont opened, they started something new called “grudge” racing, which usually took place during a weekday, in the evenings. At a grudge race anyone could make a timed run down the track, in any type of car, or race a friend in their car. All you needed was a driver’s license and a car.

One evening a friend, Gary Clark, and I drove over to Fremont to check out the grudge races in his mother’s 1950 Plymouth sedan. After watching for a while to see firsthand what it took to make a run down the track, we each took a turn making a timed run in his mother’s Plymouth to see who could run the quickest elapsed time, I was hooked for life.

After that small sampling of drag racing, I thought about making the sedan into a drag race car. But to do that I would need a trailer and a tow car, so that was out of the question. Drag racing would have to wait another couple of years before I could afford to get involved.

I never got around to installing the Oldsmobile engine in the sedan. I ended up selling it to a friend, Bob Gallagher, and helped him install it in his 1950 Mercury. Bob drove the Olds powered Merc for a year or so until it was involved in an accident. He parted the car out selling the engine to Dave Herlinger of Palo Alto who put the engine in a blue 1950 Oldsmobile, later selling the car to Lester Luther (another high school friend).

Around 1960, girls were starting to enter the picture, and I knew I would need a more comfortable car with a radio and heater that was able to drive in all types of weather. So after much thought I decided to sell the sedan and look for something a little more practical. I sold it to Jim Keck for $85.00, who lived in town and had graduated from Mountain View High School in 1958.

I never really thought much about the sedan after selling it until I attended my Mountain View High School reunion in 2006 and heard that Jim Keck was still around, living in the area. Curious to what happened to the sedan after I sold it, I looked him up in the “online white pages” and found his phone number and address in Saratoga, Ca. and gave him a call. He said he had basically stored the sedan for a couple of years not doing anything more to it, and eventually sold it to Merle Armstrong, a person he worked with at Lockheed in Sunnyvale, Ca. I tried tracking down Merle, who lived in Sunnyvale, Ca. at the time he bought the sedan from Jim, but with no luck.

Tom Chambliss

Leave a comment